Intelligent Manufacturing and Green Production Technologies in the Injection Molding Industry: Future Development Trends

With the continuous advancement of technology, the injection molding industry is undergoing significant transformation. The application of intelligent manufacturing and green production technologies not only improves production efficiency and reduces costs but also contributes to environmental conservation. Let’s discuss the application of intelligent manufacturing and green production technologies in the injection molding industry and their future development trends.

1、Application of Intelligent Manufacturing in the Injection Molding Industry

Intelligent manufacturing refers to the use of advanced information technology, automation, and artificial intelligence to achieve intelligent, flexible, and environmentally friendly production processes. In the injection molding industry, intelligent manufacturing is mainly manifested in the following aspects:

1.1、Digital Design and Simulation

Through computer-aided design (CAD) and computer-aided engineering (CAE) technologies, digital design and simulation of injection molds and products can be achieved. This not only shortens the design cycle and improves design quality but also reduces production costs.

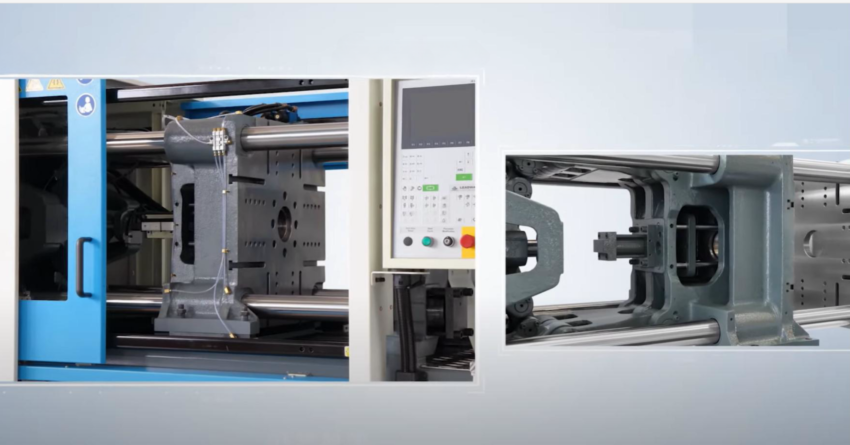

1.2、Intelligent Control Systems

Injection molding machines adopt advanced intelligent control systems to automate and optimize the production process. For example, real-time monitoring and control of injection molding machines can be achieved through sensors and actuators, thereby enhancing production efficiency and product quality.

1.3、Robotics and Automation Equipment

The injection molding industry extensively employs robots and automation equipment to automate production processes. For instance, robots can be used for mold changing, product extraction, and assembly, thereby increasing production efficiency and reducing labor intensity.

1.4、Internet and Internet of Things (IoT) Technologies

Through internet and IoT technologies, remote monitoring and management of injection molding equipment can be realized, thereby improving equipment utilization efficiency and maintenance levels.

2、Application of Green Production Technologies in the Injection Molding Industry

Green production technologies refer to the adoption of production techniques that consider resource conservation and environmental protection, aiming for sustainable development. In the injection molding industry, green production technologies are mainly applied in the following areas:

2.1、Energy Efficiency

Injection molding machines utilize efficient motors and hydraulic systems to achieve energy savings. Additionally, optimizing the production process reduces energy consumption and enhances production efficiency.

2.2、Low Noise and Low Vibration

Injection molding machines employ designs and manufacturing techniques that minimize noise and vibration, thereby improving the working environment during production.

2.3、Environmentally Friendly Materials and Processes

Injection molding machines adopt environmentally friendly materials and processes to reduce harmful emissions and minimize environmental impact. For example, biodegradable materials can be used as alternatives to traditional plastics to reduce plastic pollution.

2.4、Recycling and Reuse

Injection molding machines incorporate recycling and reuse technologies to recover and reuse waste plastics, thereby reducing resource waste.

3、Future Development Trends

With continuous technological advancements, intelligent manufacturing and green production technologies in the injection molding industry are expected to develop in the following directions:

3.1、Personalization and Customization

Through digital design and simulation technologies, injection molds and products can be personalized and customized to meet diverse market demands.

3.2、Intelligent Integration and Collaborative Manufacturing

Through internet and IoT technologies, injection molding equipment can be intelligently integrated and collaboratively manufactured, thereby enhancing production efficiency and product quality.

3.3、Green Circular Economy

The injection molding industry will further promote green production technologies to achieve resource circularity and reduce environmental impact.

3.4、Artificial Intelligence and Big Data Applications

By leveraging artificial intelligence and big data technologies, intelligent optimization and decision support can be implemented in the injection molding production process, thereby enhancing production efficiency and product quality.

4、Conclusion

Intelligent manufacturing and green production technologies are important directions for the development of the injection molding industry. By applying these advanced technologies, the industry can achieve goals of efficiency, environmental friendliness, and sustainable development, contributing to the progress of human society. However, to achieve these goals, it requires joint efforts from governments, businesses, and various stakeholders to increase research and development investment, promote technological innovation, cultivate talent, improve policy systems, strengthen international cooperation, and collectively drive the development of intelligent manufacturing and green production technologies in the injection molding industry.