The Application and Innovation of Injection Molding Machines in Luxury Goods Manufacturing

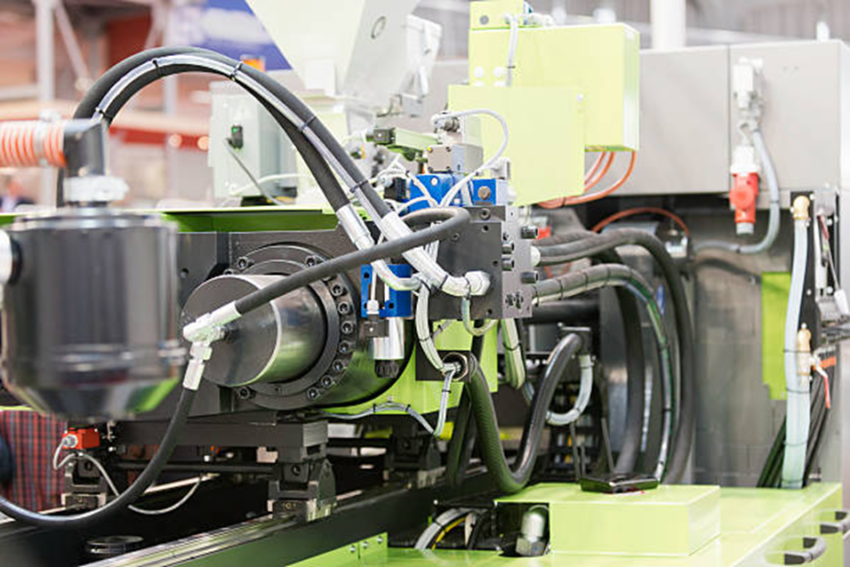

With the continuous development of technology, the application of injection molding machines is becoming increasingly widespread in various fields. Especially in the luxury goods manufacturing industry, the technological advantages and innovation capabilities of injection molding machines have brought revolutionary changes to luxury goods manufacturing. This article will detail the applications and innovations of injection molding machines in luxury goods manufacturing, as well as how to improve the quality and efficiency of luxury goods manufacturing.

1、 The Application of Injection Molding Machines in Luxury Goods Manufacturing

1.1、Precision Parts Manufacturing

An important application of injection molding machines in luxury goods manufacturing is precision parts manufacturing. Due to the high requirements for product details and quality, high-precision injection molding machines are needed to produce parts. By precisely controlling the parameters of the injection molding machine, the size, shape, and surface quality of the parts can be accurately controlled, thus meeting the high standards required by luxury goods manufacturing.

1.2、Complex Structure Forming

Luxury goods often have complex structures and exquisite appearances, which pose a high technical requirement for injection molding machines. Injection molding machines can achieve the forming of complex structures through multi-stage injection, multi-cavity, multi-material technology, providing strong technical support for luxury goods manufacturing.

1.3、High-Quality Surface Treatment

The surface treatment requirements of luxury goods are very high, requiring smooth, flawless, wear-resistant effects. Injection molding machines can achieve precise control of the product surface through adjustments to the mold design and injection parameters, thereby improving the product’s quality and aesthetic appeal.

2、Innovations of Injection Molding Machines in Luxury Goods Manufacturing

2.1、Intelligent Technology Application

With the development of intelligent manufacturing technology, injection molding machines are also developing towards intelligence. Through the introduction of sensors, controllers, and artificial intelligence technology, injection molding machines can achieve automatic adjustment of parameters, automatic detection of faults, automatic optimization of the production process, and other functions, thereby improving production efficiency and product quality.

2.2、Environmental Protection and Energy Conservation Technology Application

Environmental protection and energy conservation are important development directions for the current manufacturing industry. Injection molding machines achieve effective use of energy and reduce environmental pollution through the use of high-efficiency energy-saving hydraulic systems, low-energy consumption motors and frequency converters, etc. In addition, injection molding machines can also recycle and reuse waste plastics to achieve resource recycling and reduce production costs.

2.3、Personalized Customization Technology Application

With the increasing demand for personalized products from consumers, luxury goods manufacturing also needs to achieve personalized customization. Injection molding machines achieve precise control of product shape, color, and texture through the introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) technology, thus achieving personalized customization.

3、 Methods to Improve the Quality and Efficiency of Luxury Goods Manufacturing

3.1、Optimize Mold Design

Molds are the core components of injection molding machines, and their design directly affects product quality and production efficiency. By optimizing mold design, precise control over product size, shape, and surface quality can be achieved, thereby improving product quality and production efficiency.

3.2、Rigorous Control of Injection Parameters

Injection parameters are key factors affecting the quality of product forming. By strictly controlling injection speed, pressure, temperature, etc., precise control over the product forming process can be achieved, thereby improving product quality and production efficiency.

3.3、Improve Operator Skills

The skill level of operators directly affects the operating efficiency of injection molding machines and product quality. By strengthening operator training and skill upgrading, the operating efficiency of injection molding machines and product quality can be improved.

3.4、Introduce Advanced Management Systems

Through the introduction of advanced production management systems, real-time monitoring and data analysis of the production process can be achieved, thereby optimizing and improving the production process and improving production efficiency and product quality.

In conclusion, the application and innovation of injection molding machines in luxury goods manufacturing have brought revolutionary changes to luxury goods manufacturing. By optimizing mold design, strictly controlling injection parameters, improving operator skills, and introducing advanced management systems, further improvements in the quality and efficiency of luxury goods manufacturing can be achieved. With the continuous development of technology, the application of injection molding machines in luxury goods manufacturing will become more extensive, bringing more innovations and breakthroughs to luxury goods manufacturing.

4、The future development trend of injection molding machines in luxury goods manufacturing can be summarized as follows:

4.1、Digital and Intelligent Development:

With the continuous development of digital and intelligent technologies, injection molding machines will achieve a higher level of automation and intelligence. By incorporating IoT, big data, and artificial intelligence technology, injection molding machines can perform real-time monitoring, intelligent analysis, and optimization adjustments of the production process, thereby improving production efficiency and product quality.

4.2、Green and Sustainable Development:

Environmental protection and energy conservation are important development directions in the current manufacturing industry. Injection molding machines will adopt more efficient and energy-saving hydraulic systems, low-energy consumption motors, and frequency converters to effectively utilize energy and reduce environmental pollution. Additionally, through recycling and reusing waste plastics, injection molding machines will promote resource recycling and reduce production costs.

4.3、Personalization and Customization Development:

As consumer demand for personalized products continues to increase, luxury goods manufacturing also needs to achieve personalized customization. Injection molding machines will incorporate computer-aided design (CAD) and computer-aided manufacturing (CAM) technology to precisely control product shape, color, and texture, thus enabling personalized customization.

4.4、High-end and Brand Development:

With increasing market competition, luxury goods manufacturing companies need to continuously enhance product value and brand influence. Injection molding machines will provide higher precision and better quality products, helping luxury goods manufacturing companies achieve high-end and brand development.

In conclusion, the application and innovation of injection molding machines in luxury goods manufacturing have brought revolutionary changes to this field. By optimizing mold design, strictly controlling injection parameters, improving operator skills, and introducing advanced management systems, the quality and efficiency of luxury goods manufacturing can be further improved. With the continuous development of technology, the application of injection molding machines in luxury goods manufacturing will become more widespread, bringing more innovations and breakthroughs to this field. The future development trends of injection molding machines in luxury goods manufacturing will be characterized by digital and intelligent development, green and sustainable development, personalization and customization development, and high-end and brand development.