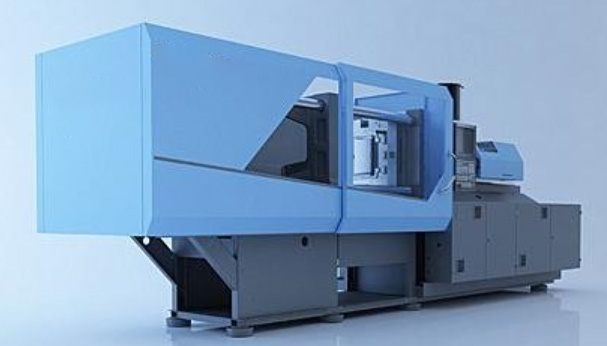

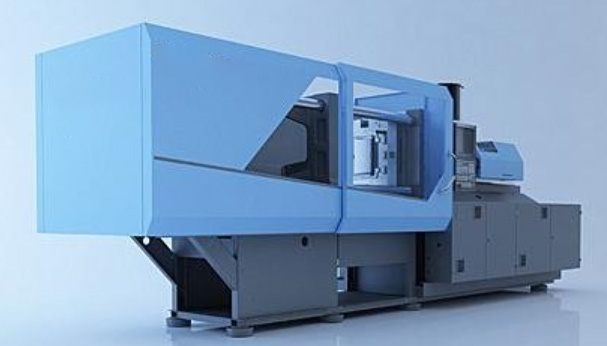

The Delicate Balance Between Key Parameters of Injection Molding Machines and Product Quality

Injection molding is a crucial process in the plastic processing industry. It involves injecting molten plastic into molds and forming the final product after cooling and solidification. During this process, two critical parameters, injection speed and holding pressure time, directly influence the quality, dimensional stability, and physical properties of the products. Let’s discuss how these parameters affect the quality of injection-molded products and provide some recommendations for optimizing them to improve product quality.

Injection speed, which refers to the rate at which the plastic material is injected into the mold, has a significant impact on both the intrinsic quality and appearance of the products. An appropriate injection speed ensures uniform material distribution, reduces internal stress, and helps avoid defects such as jetting marks, burn marks, and other surface imperfections. If the injection speed is too fast, it can result in excessive shear stress, causing uneven flow and high heat generation within the mold, leading to material degradation or decomposition, which affects the mechanical and visual quality of the products. Conversely, if the injection speed is too slow, it may cause gate freezing or short shots, resulting in incomplete filling and reduced production efficiency.

Holding pressure time refers to the duration during which the plastic material is held under a certain pressure after injection until it cools and solidifies. The holding pressure time directly affects shrinkage, warpage, and dimensional accuracy of the products. An appropriate holding pressure time ensures that the plastic fills the mold cavity completely and compensates for the material’s natural shrinkage, resulting in dimensionally stable products. Insufficient holding pressure time may lead to sink marks or shrinkage defects due to excessive material shrinkage, while excessive holding pressure time can lead to overcompaction, increased internal stress, and even difficulties in mold release and decreased production efficiency.

To optimize injection speed and holding pressure time, engineers typically need to conduct experiments and adjustments based on different material characteristics, product geometries, and mold designs. For example, high-viscosity materials or complex product structures may require a reduction in injection speed to avoid excessive shear and material degradation. Similarly, for large or thick-walled products, an extended holding pressure time may be necessary to ensure complete filling and solidification of the material.

In practical applications, intelligent control systems in injection molding machines can assist operators in finding the optimal injection speed and holding pressure time by monitoring and adjusting these parameters in real-time. Additionally, the use of simulation software for injection molding process analysis enables the prediction and optimization of these key parameters before production, saving costs and shortening the product development cycle.

In summary, injection speed and holding pressure time are two crucial parameters in the injection molding process. They not only affect the appearance quality of the products but also determine dimensional stability and physical properties. By carefully controlling and optimizing these two parameters, significant improvements in the quality and production efficiency of injection-molded products can be achieved. Therefore, understanding the impact of injection speed and holding pressure time on product quality is essential for any engineer or technician involved in injection molding.